The manufacture of form springs and formed wire

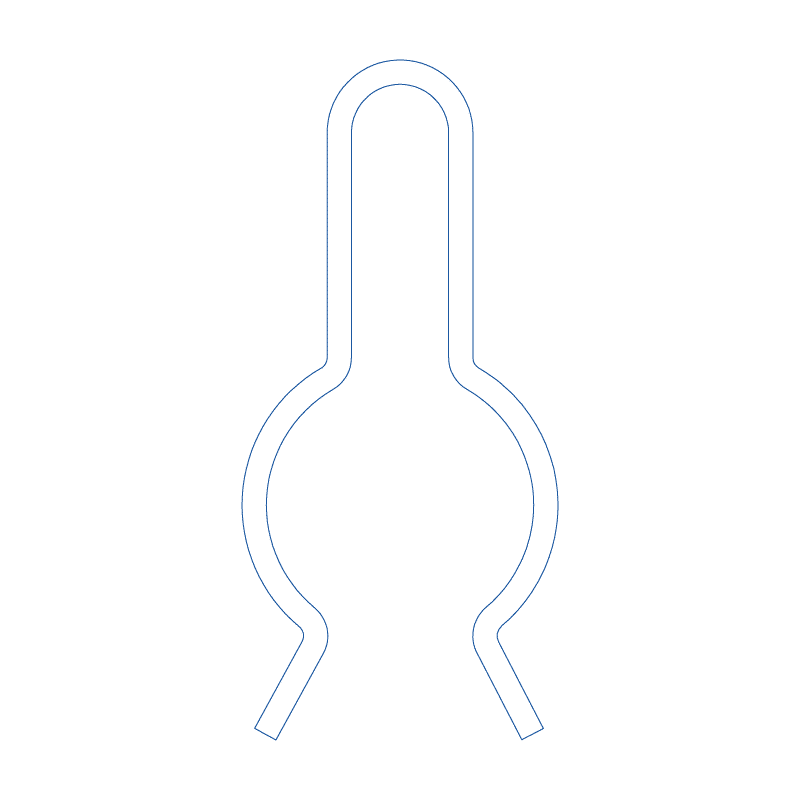

The formed wire or spring form is a metallic wire, mostly cylindrical of any length to which a desired shape is given. It is intended for a multitude of uses, since the formed wire spring can adapt to all types of working environments.Indeed, the yarn is worked, folded and cut. It undergoes several treatments depending on the task for which it is designed.

The formed wire groups together all solutions from wire, it can either have a spring function or not according to its design. In the case where it acts as a spring, its main characteristic is the elasticity and shape memory of its material as helical springs.

Use of the form spring

The formed wire can therefore be applied in many fields of activity and for many different uses due to its custom manufacturing. It can be used as a substitution of a spring or simply as a hook for example. However, here are some examples of uses for which the formed wires are most commonly used :

Create one or more movements

Guide a movement

Serve as an axis

Secure, block or immobilize a movement or a component

In use as a replacement for a compression, tension, torsion, flat spring

Control a movement

Hold and carry a mass or object

Align two masses together

Stitching a material

Entering a shaft or being inserted into a bore

Assemble parts

Transforming a movement

Function of the form spring

The formed wire has no precise function. It is intended for different uses and is found everywhere in the environment. It is a work of bending and cutting of metallic wire for use always on measure. Its operation is based on the characteristics that were defined before manufacture. The characteristics that will be taken into account are the material used, the shape given to the wire and obviously its size.Then the dimensional characteristics play an important role in the functioning of the part, but they also vary a lot.

Some formed wires may have spring function, but its applications vary greatly depending on the model. It can also very well have a hook function, thread guide, wrist, pin, needle… As much.

Bore

Since a bore is a hollow part in a cylinder, the formed wire can be integrated into it without great stress. Generally the formed wire is relatively small in size and easily adaptable to all environments.

Height

The maximum and minimum height varies according to the functions for which it was created.

The manufacturing methods of the form spring

As with the manufacture of springs, the wire formed is made with a wire of any diameter, the material used for its design varies according to the use of the part. This can be mild steel, which has no spring effect, or spring steel for formed wires that will have spring properties. There are of course other stainless steel materials or galvanized steel. The material can also undergo surface treatments as for coil springs because the yarn formed can quite possibly undergo the same environmental stresses. Then the manufacture of the formed wires consists mainly in cutting the wire and folding it. A folding performed either by machine :

NC forming : Forming from a CNC bending machine. FMU 32 forming : Performs forming by automatic production using 32 mechanical axes.

However, from 3.2 mm wire diameter onwards, the bending must be manual because the machine cannot carry out the work beyond this diameter.