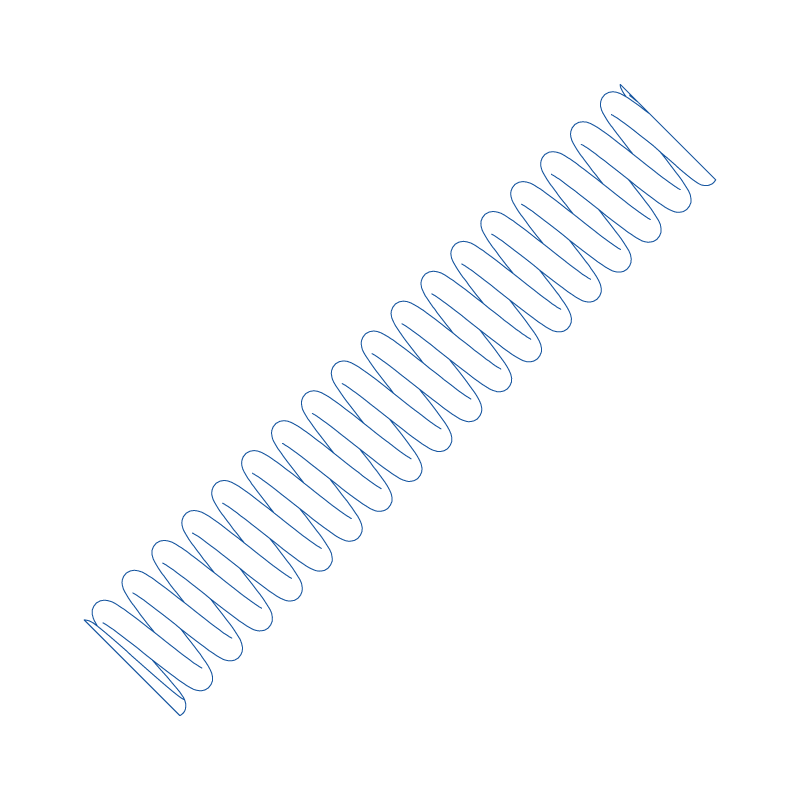

The manufacture of the custom compression spring

The most widely used compression spring in almost all areas of activity. It is intended to undergo compression deformation. Of helical shape, there are different types: conical springs, biconic springs, variable pitch springs, constant pitch springs… In the manufacture of compression springs, many parameters are taken into account. The characteristics of the compression spring will depend on its application and the environment in which it will be used.

Use of the compression spring

When a machine is equipped with springs, they can have several functions:

Damping a shock

Create a movement

Control a movement

Guide a movement

To undergo pressure between two masses

Undergoing compression and at the same time a slight torsion (less than 15%)

Prevents friction between two elements

Counter a force that is applied against him

Remove vibrations

We see that there may be several possible jobs, depending very much on its environment. It can be used as a return spring or to improve safety, comfort, increase the life of a machine… To perfectly meet expectations, know-how and domain knowledge are paramount.The accompaniment and the realization of custom-made springs can be a plus.

Function of the compression spring

It works on a longitudinal axis. When the diameter is constant, the compression spring offers a constant stiffness. With each mm of additional compression, it delivers the same amount of additional force. When the diameter is variable, it offers parabolic stiffness, almost exponential. Thanks to our compression springs, its elastic deformation compresses until the coils are joined to the maximum. It then regains its initial shape thanks to the recall of the force, acquired during its course.

Kinetic energy

When a mass exerts a force on the compression spring, it is reduced in volume by compression. When it returns to its natural position, the mass gains speed and is projected further than the end of the spring. This energy is created by movement when it works, this is called kinetic energy.

Potential energy

It was the work done by force that allowed the compression. That is to say, the potential energy is negative when it is in compression work. The energy is positive when the compression spring returns to its natural position because it gives way to its energy. It can be seen that this potential energy is zero when the spring is not compressed.

Each type of spring operates on the same principles. However, the use varies depending on whether they are tension springs, torsion springs, flat springs or form springs.

Define its compression spring to measure

In the manufacture of custom compression springs, there are essential elements. For the spring to produce a quality movement, the measurements are important. For the design of a compression spring the necessary points to know are:

- Wire diameter

- Outside diameter or inside diameter

- Free length

- Number of coils or pitch

- Material

Most often, we find springs made of steel or stainless steel. Steel has a better effect than stainless steel but is less resistant to conditions. Indeed, unlike steel, stainless steel, whether 302 or 316, resists temperatures up to +200° and -180°. In addition, steel requires surface treatment to resist corrosion. Stainless steel is more resistant.

Different types of ends :

- Not ground ends, not close together

- Not ground ends, close together

- Grinded ends, not close together

- Grinded ends, not close together

Different body forms :

- Straight

- Conical

- Biconicals

- Diabolo